- Home

- Products

- Superconducting Equipment

- The First Nonvolatile 5.5T Cryogenic ...

- Series RCSC Superconducting Iron Sepa...

- Powder Processing Equipment

- Dry Quartz-Processing Equipment

- Series HF Pneumatic Classifier

- Ball Mill&Vertical Classifier Product...

- Ball Mill &Horizontal Classifier Prod...

- WHIMS

- Global Third generation Vertical High Gr...

- Global Fourth -generation Vertical High ...

- The Global latest generation 1.8T evapor...

- Cylinder screen

- Magnetic Separator

- Series CTB Permanent-Magnetic Drum se...

- Series JCTN Raising Cocentrate grade ...

- Series CTY Wet Permanent Magnetic Pre...

- 1.8m Magnetic Separator

- Iron Separator

- Series RCDB Dry Electric-Magnetic Iro...

- Series RCDC Fan-Cooling Self-Cleaning...

- Series RCDD Self-Cleaning Electric Ma...

- Series RCDE Oil-Cooling Electromagnet...

- Non-Ferrous Metal Separation System and magnetic stirrer

- Series HTECS eddy current separator

- Completely non-ferrous metal separat...

- Complete Set of Mining Equipment

- Single Driving High Pressure Roller ...

- Processing Line for Iron Ore Concent...

- Series YCW Dry Discharge Reclaimers

- Series GYW Vacuum Permanent Magnetic...

- Others Mining Equipment

- Series DZ Motor Vibration Feeder

- Series GZ Electromagnetic Vibration F...

- RGT High-Frequency Pulse Demagnetizer

- Series JYG-B Metal Detector

- News

- Case

- Contact us

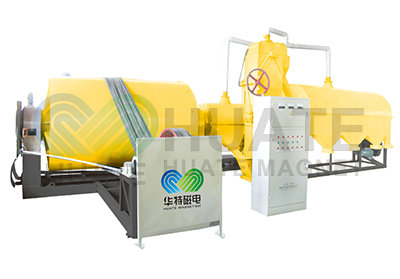

Ball Mill &Horizontal Classifier Production Line

Type: Powder Processing EquipmentService hotline:400-658-3198

send e-mail: raul@chinahuate.com

- Applicable Scope

- Technical Features

Brief Introduction

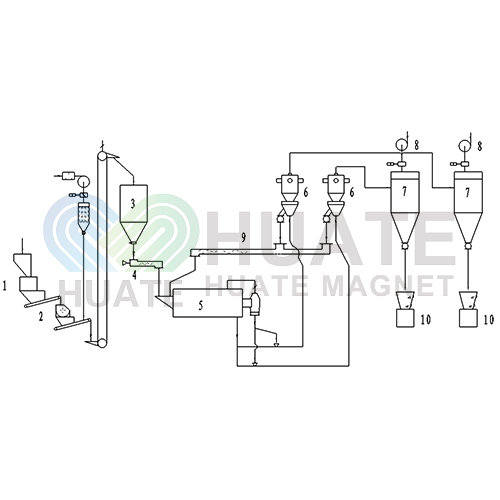

The whole process of the technology ensures that the emission of dust is lower than 40 mg / m³ and 20 mg / m³ after production, by adopting the combination of dust collector, draft fan and Pneumatic Conveying System, the strict control of every dust point, and the use of high-quality filter material. The equipment can prevent dust leak and make the whole technological process negative and clean.

Features of Main Device

Ball Mill

☆Designed to the standards of ultrafine mineral manufacturing.

☆Optimized length-to-diameter factor of ball mill

☆Grid plate at the end of the ball mill discharges powder fluently, no dilating and no necessary to cool the tube

☆Grinding medium chosen according to customers’ product, high filling rate and efficiency

☆Perfect match between drive station and energy consumption of grinding, energy saving to the fullest extent possible.

☆Forming a closed system with classifier, with negative pressure transport, without powder pollution.

Classifier

☆Using HFW multi-rotor classifier.

☆Precise procedure control to ensure good top-cutting.

☆Cleansing air adjustable to improve classifying efficiency.

☆Optimized rotor design for energy saving.

☆Diversified particle distribution by different arrangement of classifiers to satisfy different techniques requirement.

Dosing System

☆The material feeding of ball mill is controlled by precise dosing system, and then when density changed stable feeding still can be assured.

☆The material feeding of classifier is controlled by precise dosing system, and interlocks with outlet of ball mill, to make sure the stability of system operation and particle size.

☆Precise dosing pump would spray grinding aid by precise time and dose according to the requirement of particle size.

☆Both the silo and bucket elevator are installed with level indicators to achieve automatic control of the whole product line.

☆PLC control device is used to indicate clearly operational status, normal or wrong, and very easy to operate

Environmental Protection and Noisy Regulation

☆Membrane filtering bag is adopted, and the rate of pollutant powder discharge is lower than 20mg/m3.

☆High performance silencer is adopted, and the noise is lower than 80dB(A).

☆No wastewater would be released.The cooling water in the bearing of ball mill could be used recyclingly.

scope of arrangement:

1、 Soft material: calcite, marble, limestone, barite, gypsum, slag etc.

2、 Hard material: quartz, feldspar, carborundum, corundum, fine cement, Zircon, etc.

Technological process chart